Processing

The main objective of EMEL S.r.l. is to make as many processes as possible available in order to facilitate the client in the manufacturing of anything it deems most suitable to its needs, offering assistance during the entire production cycle.

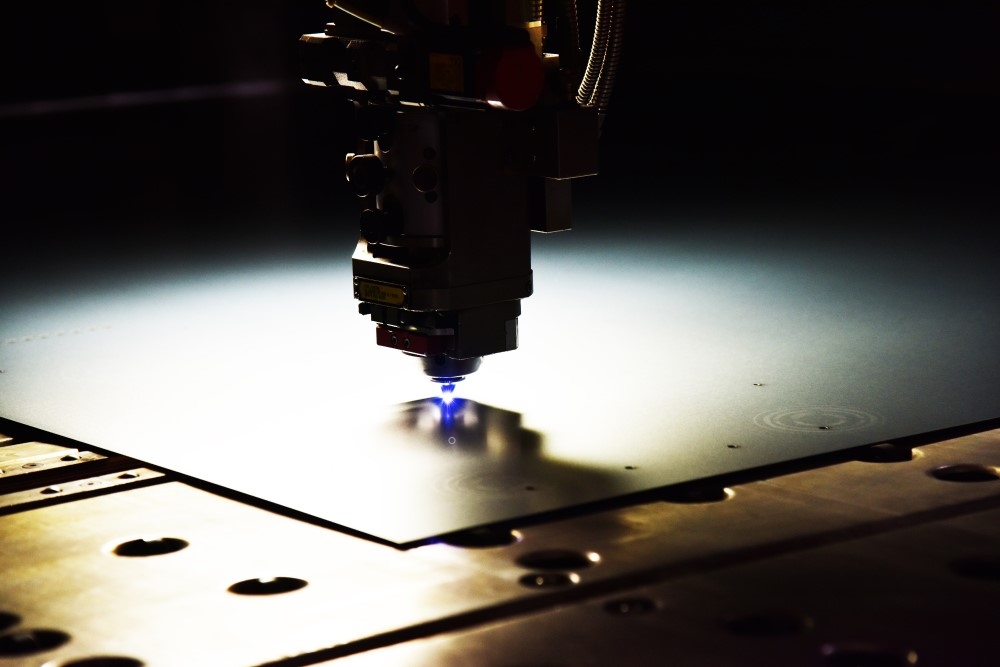

LASER CUTTING

The cutting process using the EM radiation beam is offered by our company through cutting-edge technologies, which allow us to carry out extremely precise machining in a very short time.

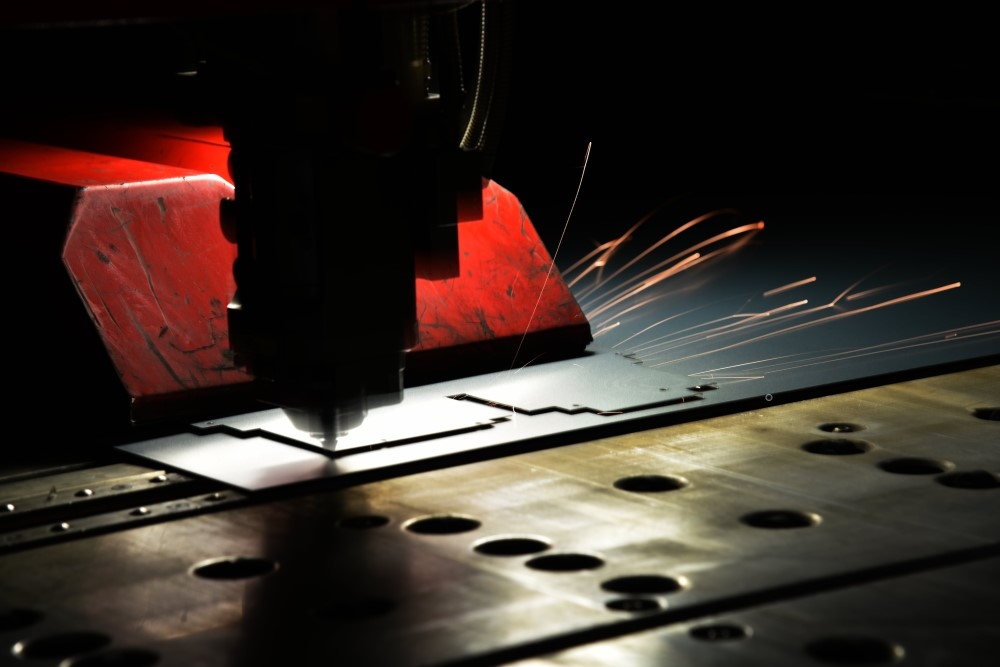

LASER/PUNCHING COMBINATION

The technology used to cut, drill, thread, emboss, create etching or openings on the metal sheet, also thanks to the creation of “ad hoc” punches. The use of two complementary methods – laser and punching – allows a considerable reduction in production times.

BENDING

Established as a company specialized in sheet metal bending, EMEL S.r.l. guarantees quality results that are suitable for every need, thanks to the use of the latest generation of manual and automatic bending and paneling machines.

PRESSING

Cold pressing of sheet metal is the process used to create shapes, parts and folds that cannot be made by using common operating machines. Generally, the creation of a dedicated mold is a process suitable for large batches.

ASSEMBLY

We have an assembly department that allows us to facilitate the assembly work of the client. For this purpose, we use small pressure or capacitor discharge parts, or the application of double-sided adhesives or biocomponent adhesives.

FINISHES

We are able to create a large variety of finishes, from stainless steel satin finishes to tumbling or electrochemical polishing. We also offer the possibility of painting the component on specific request.

WELDING

Our welding department is equipped with MIG – TIG welding machines with two dedicated manual workstations, aimed, in particular, at the welding of stainless steel components and their finishing.